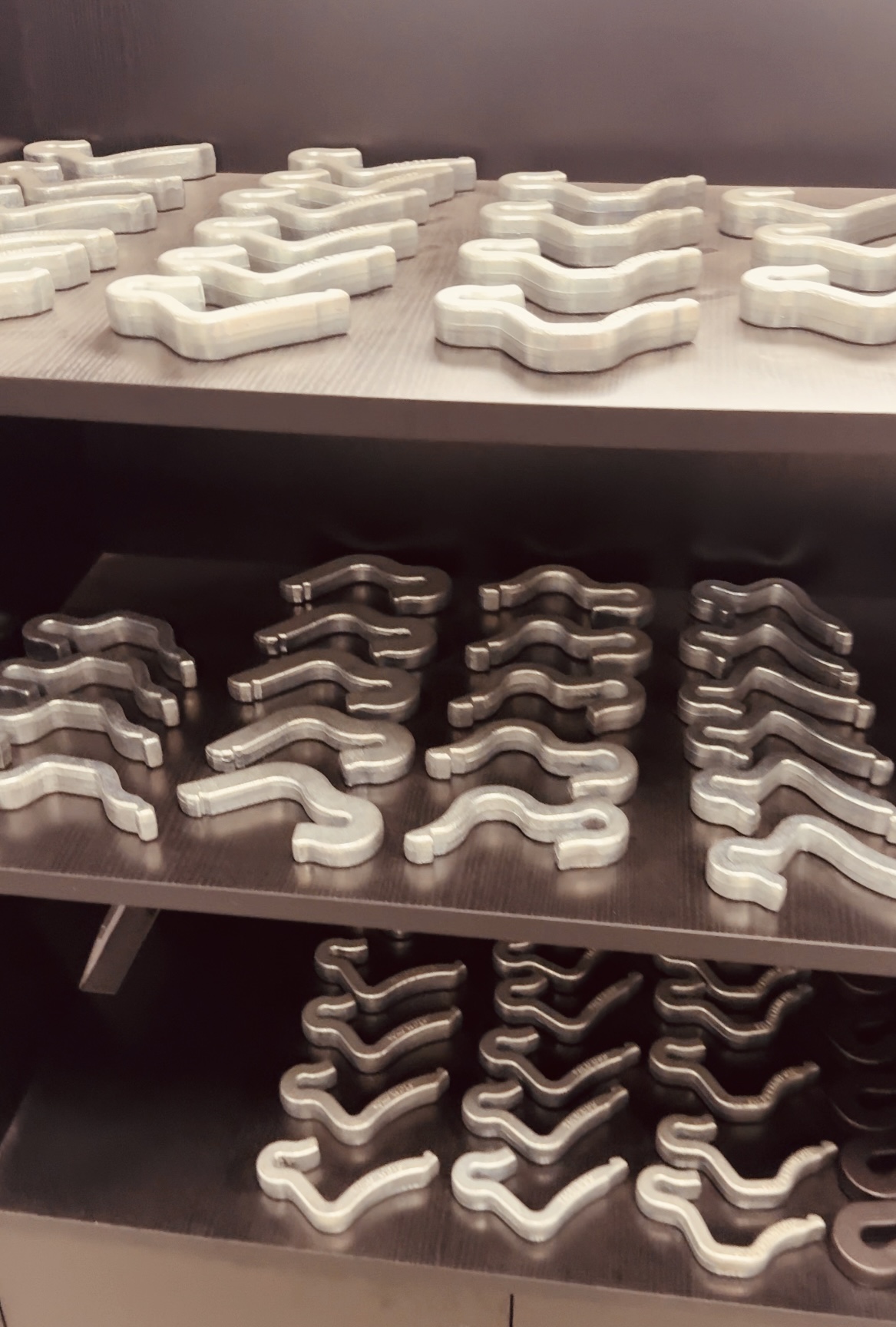

Railroad Anchors

High-Quality Railroad Anchors

Railroad Anchors, also known as anticreepers, are essential components in railway track systems designed to prevent the longitudinal movement of rails due to temperature changes, vibrations, and the weight of passing trains.

Railroad Anchors

Railroad Fasteners

Anchor Types Overview

Drive-on Rail Anchors

Drive-on rail anchors are a type of rail fastening device designed to prevent the longitudinal movement of rails, commonly referred to as “rail creep.” These anchors are essential for maintaining the stability and safety of railway tracks. Here is a detailed overview of drive-on rail anchors based on the provided sources

Anchors Materials

- Surface: Plain (oiled), color painting, zinc painted, or hot-dip galvanized.

- Standards: AS1085.10-20002, DIN, ISO-9001

Drive-on Rail Anchors

IMPROVED FAIR ANCHOR

Our enhanced anchor meets AREMA standards for holding power, offering increased stability and durability. Designed with top-tier materials and innovative technology, it ensures exceptional performance and reliability in rigorous railway environments.

Material: 65 Manganese

Brinell Hardness: 370 – 400

Size: 100RE, 115RE,136RE

Spring Type Rail Anchors

Unit 5-On ANCHOR

Unit anchors are another type of spring rail anchor, similar to Trueloc anchors, designed to fasten the rail base and exert anti-creeping force against the edge of the tie to resist rail movement

Material: 60Si2MnA Spring Steel

Surface Treatment

Size: 100RE, 115RE,136RE

How it works

Manufacturing Process

1.

Product Design and Verification

During production, we perform in-process inspections and apply statistical process control to continuously monitor quality, ensuring all final products meet or exceed AREMA standards through rigorous testing

2.

Material Selection

We source high-quality materials that comply with AREMA standards and conduct material testing to ensure durability and suitability for railway applications.

3.

Manufacturing Process

Our approach involves using advanced manufacturing techniques for precision and quality, regularly training staff on AREMA compliance and new technologies, and conducting routine machinery maintenance to prevent faults and maintain consistent product quality.

4.

Quality Assurance

During production, we conduct in-process inspections and tests to detect any deviations from the standard. We apply statistical process control to monitor quality continuously and ensure that final products undergo rigorous testing to meet or exceed AREMA standards.

5.

Documentation and Traceability

We maintain detailed records of all production batches, including material certificates, manufacturing conditions, and inspection results. A traceability system is implemented to track products from raw materials to finished goods.

6.

Product Sampling and Hardness Testing

Sample the product to measure its hardness using a Brinell hardness tester, ensuring it meets the required specifications for durability and performance.

Frequently Asked Questions

What are railroad anchors??

Railroad anchors, also known as rail anticreepers, are devices used to prevent the longitudinal movement of rails, commonly referred to as “rail creep.” They are essential components in railway track systems, ensuring the stability and safety of the tracks by holding the rails in place against the forces exerted by passing trains, temperature changes, and vibrations

What materials are used to make railroad anchors?

- Heat-Treated Steel: Provides high strength and durability, essential for withstanding the forces exerted by passing trains and environmental conditions.

- Spring Steel: Known for its high yield strength and ability to return to its original shape after deformation, making it suitable for dynamic forces.

- Ductile Iron: Used in some markets, such as Russia, for high-grade ductile iron castings.

What types of railroad anchors are there?

- Drive-on Rail Anchors: These are driven onto the rail base using tools like hammers. They are commonly used in areas with heavy train traffic and can be used with most types of rail sizes and materials.

- Spring Type Rail Anchors: Made from heat-treated steel or spring steel, these anchors are designed to be durable and withstand high levels of stress and vibrations. They are commonly used in areas with heavy train traffic.

Where can I purchase ANCHOR products?

Contact Starpath Rail Material Supply

Have additional inquiries?

We are here to help. Let’s engage in a conversation.