Manufacturer

Forging & Powder Metallurgy

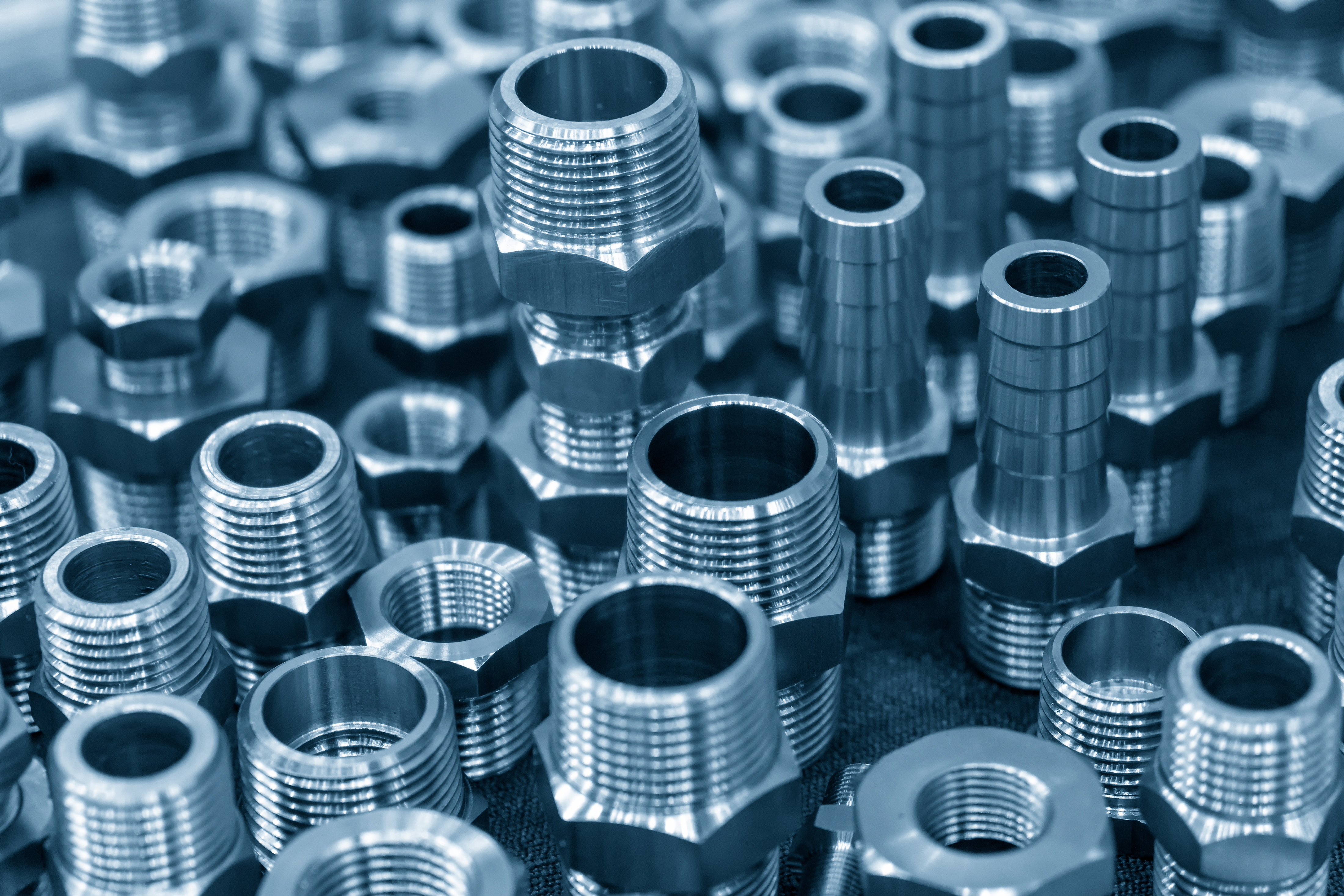

Custom Built Solutions: Forging and Powder Metallurgy

Custom Built Manufacturing

Forging and Powder Metallurgy are advanced manufacturing techniques that are pivotal in producing parts with exceptional strength and precision.

Our numerous PRODUCTION LINES are strategically designed to optimize product availability, ensuring a consistent and reliable supply of high-quality components.

Forging Parts

Versatile manufacturing method used to create parts from various metals by applying compressive forces.

Powder Metallurgy

Produce parts with very precise and uniform properties, which are essential for high-performance applications in industries.

Custom Built Manufacturing

Industries Served

Transportation

Railway, marine, and aerospace components, where high performance and safety standards are critical.

Automotive Industry

Produces critical components like gears, axles, levers, and crankshafts that must withstand extreme stress and fatigue.

Medical Equipment

The company forges and molds parts for surgical instruments and implants, such as hip and knee replacements. Additionally, it produces components for diagnostic devices that require high precision and biocompatibility.

Electronics & Appliances

Uses precision parts in the manufacturing of large-scale servers, cooling systems, and even in smaller household appliances.

Aerospace Industry

Utilizes high-strength, lightweight forged and powder metallurgy parts for critical applications in aircraft structures, landing gear, and engine components.

How it works

Custom Built Manufacturing Order Process

1.

Sample or Drawing Submission by Customer

The process starts with the customer providing a sample or drawing, detailing their specific requirements and specifications for the custom product.

2.

Mold Creation and Prototype Testing

A mold is created based on the initial sample or drawing, and a prototype is then developed. Subsequently, the prototype is tested to ensure that the required specifications and customer expectations are met.

3.

Quotation and Approval

Once the prototype is approved, a detailed quotation is subsequently prepared and then sent to the customer for review. This quotation, moreover, includes all costs associated with the project, such as materials, labor, and any additional services.

4.

Order Confirmation and Deposit

Upon acceptance of the quotation, the customer confirms the order and pays a deposit. This deposit typically covers the cost of materials and part of the labor.

5.

Manufacturing

Once the deposit is received, the manufacturing of the product promptly begins. During this stage, the process adheres strictly to the approved prototype’s specifications.

6.

Quality Control

Our team implements rigorous quality control measures throughout the manufacturing process to ensure every aspect of the product meets or exceeds the agreed-upon standards.

7.

Final Review and Adjustments

After manufacturing, the product undergoes a final review with the customer. Any necessary adjustments are made to ensure full customer satisfaction.

8.

Final Payment

Before delivering the product, the customer makes the final payment. At this stage, we conclude all the financial transactions related to the project.

Call to Action

Transform Your Industry Standards with Precision

Join the forefront of innovation with our state-of-the-art solutions

Unmatched Quality Assurance

Customization at Its Core

Leading Industry Expertise

Dedicated Customer Support