Are you struggling with rail movement? Discover how rail anchors can revolutionize your track maintenance strategy!

Rail anchors are essential components in railway systems that prevent longitudinal rail movement. This comprehensive guide covers their design, installation, maintenance, and benefits, helping railway engineers and maintenance professionals ensure track stability and safety.

Table of Contents

- Introduction: The Critical Role of Rail Anchors

- Understanding Rail Anchors: Design and Function

- Installation Process: Mastering the Art of Anchor Application

- Maintenance Best Practices: Ensuring Long-Term Performance

- Advantages of Rail Anchors: Why They’re Industry Favorites

- Case Studies: Real-World Success Stories

- Future Trends: Innovations in Rail Anchor Technology

- Conclusion: Embracing Rail Anchors for Superior Track Stability

Introduction: The Critical Role of Rail Anchors

In the complex world of railway engineering, one component stands out as a crucial guardian of track stability: the rail anchor. These unassuming yet powerful devices play a pivotal role in preventing rail movement, a phenomenon that can lead to track misalignment, increased maintenance costs, and even catastrophic derailments.

But what exactly are rail anchors, and why are they so important? Let’s dive into the world of railway track components and discover how these small but mighty anchors keep our trains running smoothly and safely.

Understanding Rail Anchors: Design and Function

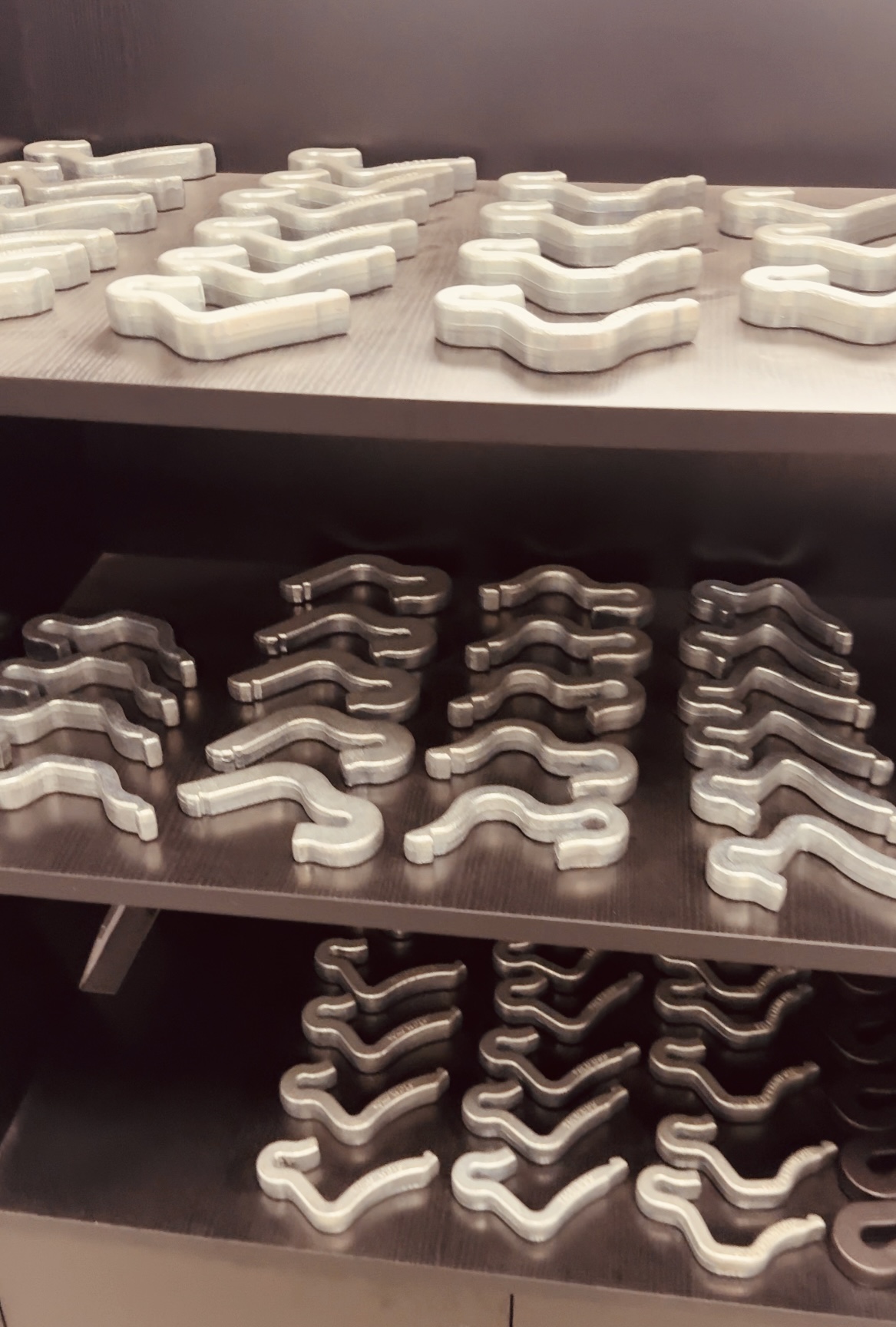

Rail anchors are ingeniously designed fastening devices that secure rails to sleepers or ties, effectively resisting longitudinal forces that cause rail movement. Their primary function is to maintain proper rail positioning, ensuring the integrity and safety of the entire track system.

Key Features of Rail Anchors:

- Material Composition: Typically crafted from high-quality steel, rail anchors boast exceptional strength and durability. This robust construction allows them to withstand the immense forces exerted by passing trains and harsh environmental conditions.

- One-Piece Construction: The seamless, single-piece design of many rail anchors ensures reliability and simplifies installation and maintenance processes.

- Large Bearing Surface: A distinguishing feature of these anchors is their expansive bearing surface. This design element serves a dual purpose:

- It effectively lodges against both the rail base and the tie.

- It prevents cutting and wear, significantly extending the lifespan of wooden ties.

- Versatile Application: Rail anchors are suitable for various track configurations, including:

- Mainline tracks

- Open deck bridges

- Rail crossings

- Turnouts

By understanding these key features, railway professionals can make informed decisions about implementing rail anchors in their track systems. For more information on different types of rail anchors, including spring-type variants, check out our comprehensive comparison.

Installation Process: Mastering the Art of Anchor Application

The installation of rail anchors is a critical process that directly impacts their effectiveness. Follow these steps to ensure proper installation:

- Selection: Choose the appropriate rail anchor based on:

- Rail type

- Rail weight

- Expected track forces

- Preparation: Thoroughly clean the sleeper or tie, removing all debris and dirt. This step is crucial for ensuring a secure fit.

- Positioning: Place the rail anchor on the sleeper or tie:

- The curved end should face the base of the rail.

- Center the anchor on the rail base.

- Maintain consistent orientation throughout the installation process.

- Application: Drive the anchor onto the rail base using:

- Sledgehammers for manual installation

- Specialized equipment for larger-scale projects

- Securing: Drive the anchor until it’s snug against the rail base.

- Testing: After installation, rigorously test each anchor for:

- Tightness

- Stability

- Adjustments: Reposition and re-hammer any loose anchors until they’re secure.

Pro Tip: Always follow manufacturer guidelines and industry standards during installation. Proper installation is key to maximizing the performance and lifespan of rail anchors. For more information on railway standards, visit our AREMA standard railway products page.

Maintenance Best Practices: Ensuring Long-Term Performance

Regular maintenance is crucial for the longevity and effectiveness of rail anchors. Implement these best practices to keep your track system in top condition:

- Scheduled Inspections: Conduct thorough inspections at least annually, or more frequently in high-traffic areas. Look for:

- Signs of wear

- Damage

- Loosening of anchors

- Prompt Replacement: Immediately replace any anchors that are:

- Loose

- Damaged

- Showing signs of excessive wear

- Torque Maintenance: Ensure all anchors are torqued to the manufacturer’s specifications during:

- Initial installation

- Routine maintenance

- Replacement procedures

- Documentation: Maintain detailed records of:

- Inspection dates

- Findings

- Maintenance actions taken

- Training: Regularly train maintenance staff on:

- Proper inspection techniques

- Correct installation procedures

- Safety protocols

By adhering to these maintenance practices, you’ll maximize the lifespan of your rail anchors and ensure optimal track stability and safety. For more information on quality control in railway component manufacturing, check out our advanced forging quality control page.

Advantages of Rail Anchors: Why They’re Industry Favorites

Rail anchors have become a preferred choice for many railway engineers and maintenance professionals. Here’s why:

- Simplicity: Their straightforward design allows for easy installation and removal using basic tools, significantly reducing maintenance time and costs.

- Durability: Constructed from high-strength materials, these anchors offer long-term performance even under:

- Heavy loads

- Extreme weather conditions

- High-frequency train passages

- Versatility: Suitable for various track configurations, making them a versatile solution for different railway applications.

- Cost-effectiveness: The combination of simple design, ease of installation, and long lifespan makes rail anchors an economical choice for track stability. For a detailed cost analysis of railway fasteners, visit our ultimate guide to railroad fastener cost analysis.

- Enhanced Safety: By effectively preventing rail movement, these anchors significantly contribute to overall track safety.

- Reduced Maintenance: Their robust design and performance lead to fewer track alignment issues, reducing the need for frequent maintenance interventions.

- Improved Ride Quality: By maintaining proper rail positioning, anchors contribute to smoother train rides, enhancing passenger comfort.

These advantages make rail anchors an invaluable component in modern railway systems, offering a perfect balance of performance, cost-effectiveness, and safety.

Case Studies: Real-World Success Stories

Let’s explore some real-world applications of rail anchors and their impact on railway operations:

Case Study 1: High-Speed Rail in Japan

Challenge: Japan’s Shinkansen high-speed rail network faced issues with rail movement due to the extreme forces exerted by trains traveling at speeds over 300 km/h.

Solution: Implementation of advanced rail anchors specifically designed for high-speed applications.

Results:

- 40% reduction in track maintenance frequency

- Improved ride comfort reported by passengers

- Enhanced overall track stability and safety

Case Study 2: Heavy Haul Lines in Australia

Challenge: Australian iron ore transport lines experienced severe rail movement due to extremely heavy loads and harsh desert conditions.

Solution: Deployment of heavy-duty rail anchors with enhanced corrosion resistance.

Results:

- 50% decrease in rail movement incidents

- Significant reduction in derailment risks

- Extended lifespan of track components, leading to cost savings

Case Study 3: Urban Metro System in London

Challenge: London Underground faced difficulties with rail anchoring in its oldest tunnels due to space constraints and moisture issues.

Solution: Custom-designed compact rail anchors with special moisture-resistant coatings.

Results:

- Improved track stability in confined spaces

- 30% reduction in weather-related track issues

- Enhanced passenger safety and comfort

These case studies demonstrate the versatility and effectiveness of rail anchors in diverse railway environments, from high-speed lines to heavy haul operations and urban metro systems. For more information on custom solutions for railway applications, visit our custom-built manufacturing page.

Future Trends: Innovations in Rail Anchor Technology

The railway industry is constantly evolving, and so is the technology behind rail anchors. Here are some exciting trends and innovations to watch:

- Smart Anchors: Integration of sensors for real-time monitoring of:

- Anchor performance

- Rail movement

- Track conditions

- Advanced Materials: Development of new alloys and composites for:

- Enhanced durability

- Improved corrosion resistance

- Reduced weight

- Eco-friendly Solutions: Research into sustainable materials and manufacturing processes to reduce the environmental impact of rail anchors.

- Automated Installation: Development of robotic systems for faster, more precise anchor installation, especially for large-scale projects.

- Customization: Increased focus on tailored anchor designs for specific track conditions and operational requirements. Learn more about our custom forging solutions.

- Integration with Track Management Systems: Incorporation of anchor data into comprehensive track management platforms for optimized maintenance planning.

As these innovations come to fruition, we can expect rail anchors to play an even more crucial role in ensuring the safety, efficiency, and sustainability of railway systems worldwide. Stay updated on the latest trends in railroad material supply by visiting our blog.

Conclusion: Embracing Rail Anchors for Superior Track Stability

Rail anchors are more than just track components; they’re guardians of railway safety and efficiency. By preventing rail movement, these unassuming devices play a crucial role in:

- Maintaining track alignment

- Reducing maintenance costs

- Enhancing passenger comfort

- Preventing potentially catastrophic accidents

As we’ve explored in this comprehensive guide, the benefits of rail anchors extend far beyond their primary function. From their simple yet effective design to their versatility across various railway applications, these anchors have proven themselves indispensable in modern track systems.

By understanding the design, installation process, maintenance requirements, and advantages of rail anchors, railway professionals can make informed decisions to optimize their track stability strategies. As technology continues to advance, we can look forward to even more innovative solutions that will further enhance the performance and reliability of these critical components.

Embrace the power of rail anchors, and take your railway track stability to new heights!

For more information on our range of railway products and services, including rail anchors, visit our product page.